Laser Scanning Tunnels and Bridges

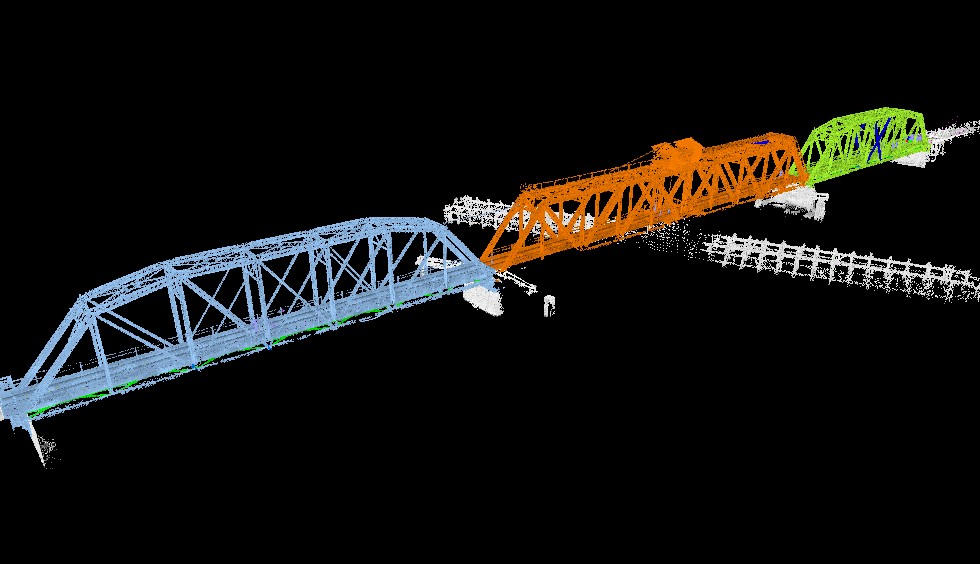

3D Scanning Revolutionizes Bridge Restoration

We team up with Rainier Welding and Legacy Contracting to solve a complex bridge restoration project, combining 3D scanning technology with bridge building expertise.

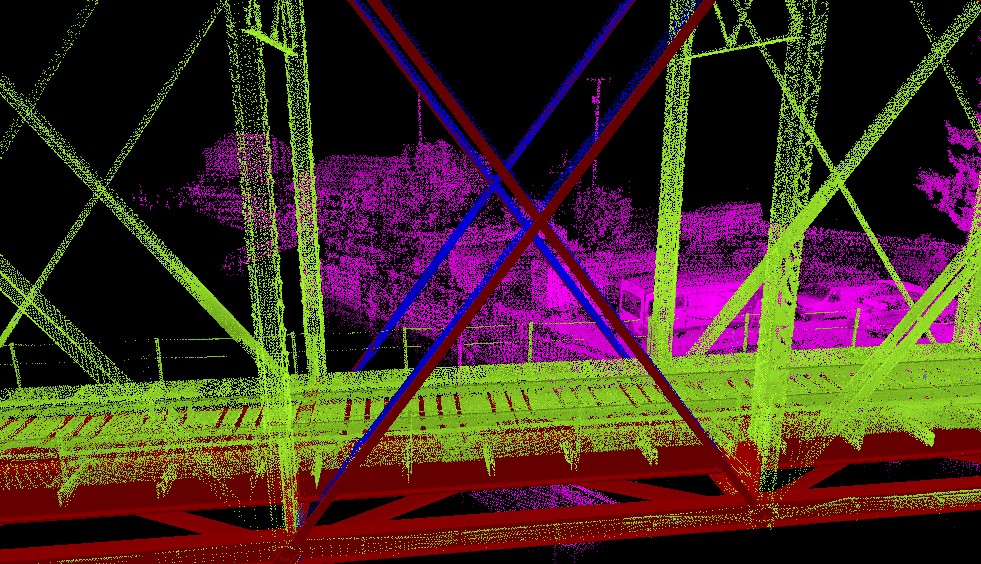

How 3D Scanning Transformed the Process

- Eliminated Manual Templates: 3D scans replaced field-made templates, reducing human error.

- Captured Rivet & Bolt Patterns: Scans identified general rivet locations and structural variations in the original bridge. The precise dimensions and bolt patters required Kohera3D software and expert analysis, and lots of math!

- Created Digital Replicas: Using Scan-to-Plan™ technology, scan data is converted into highly accurate 3D models, ensuring fabricated components would fit precisely.

- Streamlined Fabrication: Rainier Welding, from 500 miles away, used the digital scan data to accurately detail and fabricate replacement components before arriving on-site, drastically reducing installation time. Parts could be painted and numerically identified, ready to install.

Read more on Rainer Welding's blog page

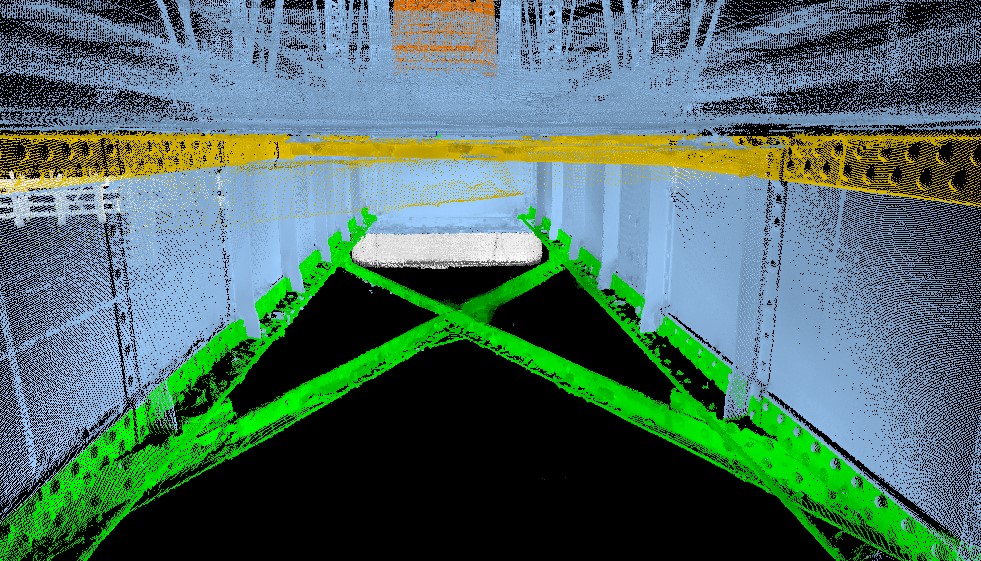

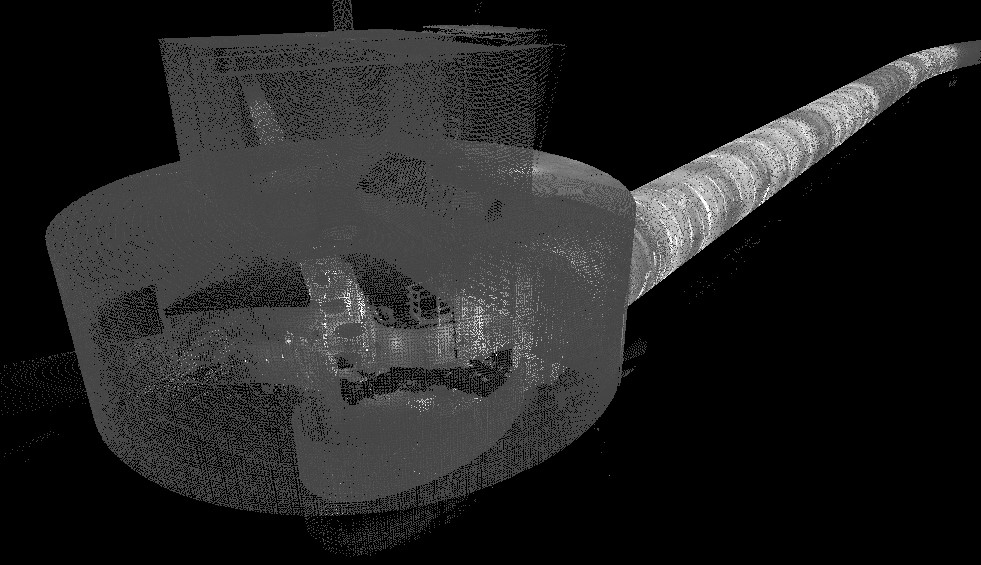

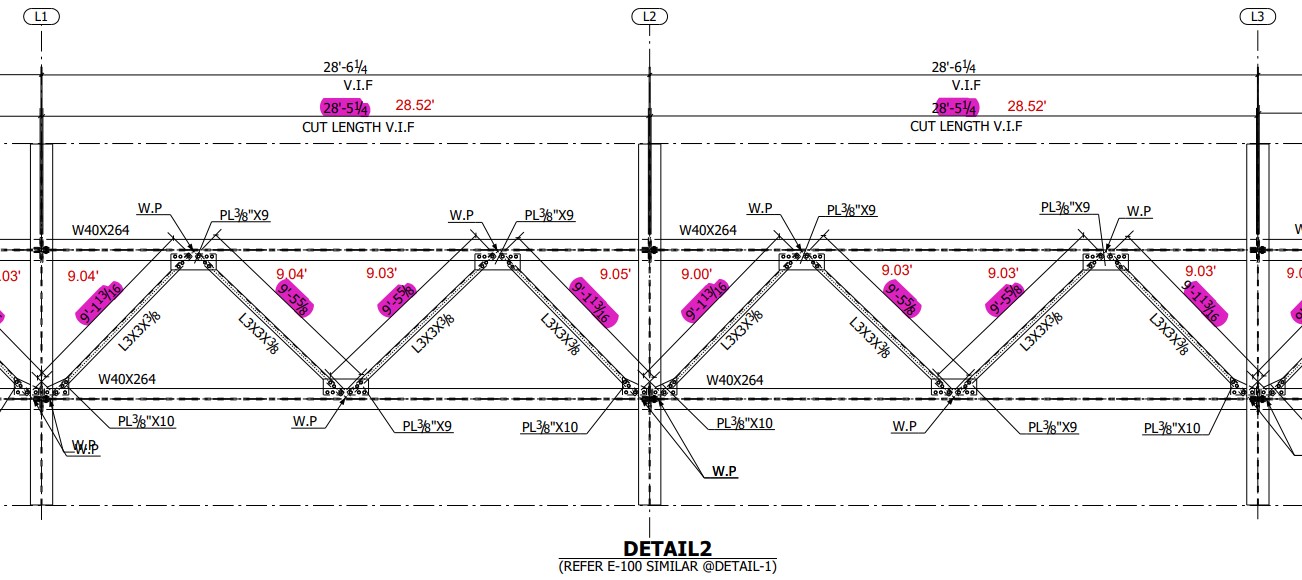

Laser scanning for bridge repairs, modifications, and dimension verification.

Bridge Repair Plan marked up with real life dimensions as captured by the laser scanner.

See also Nooksack River Bridge Repair

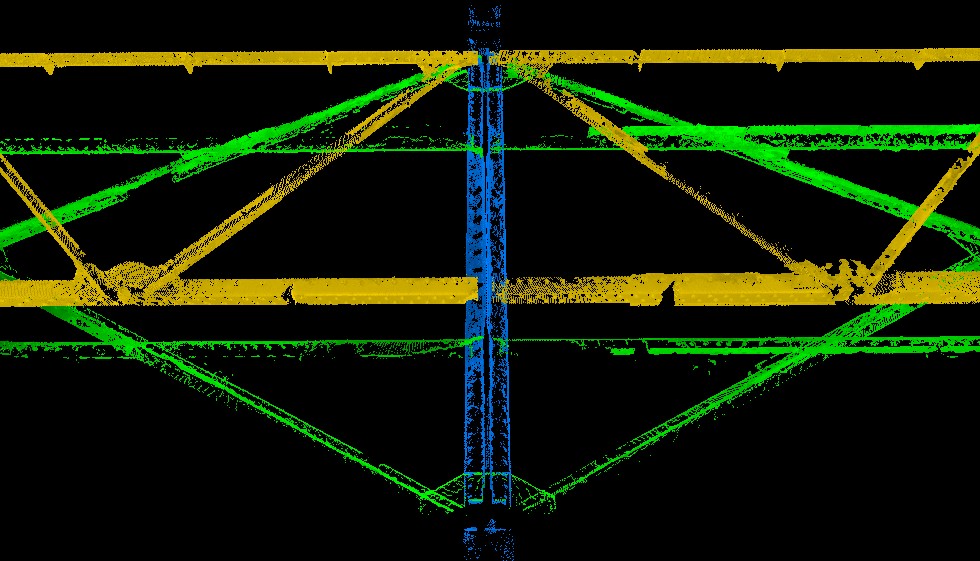

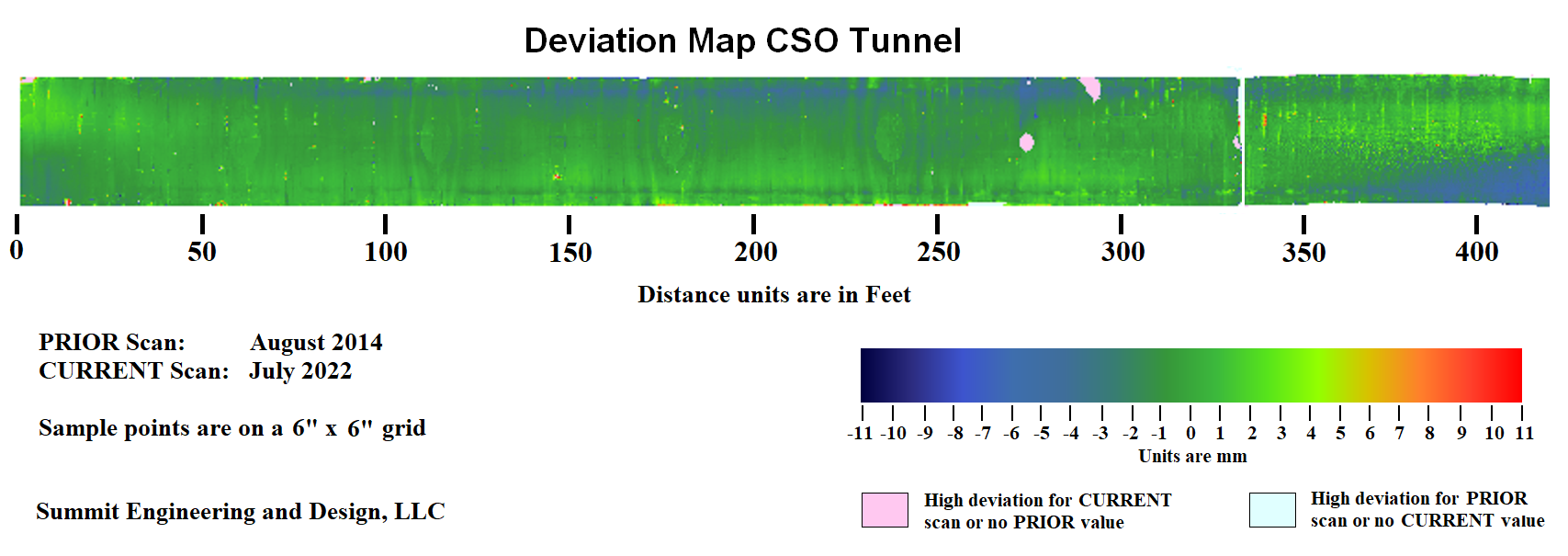

Laser scanning tunnels for deviation mapping.

Purpose of scanning was to record the position and condition of the concrete structure. In the event of seismic shifts, the scan data will be used to analyze positional movement in the walls of this tunnel.

Deviation map using the first round of scanning performed in 2014 to a second round of scanning in 2022.

See also Tank Shell Deviation Map